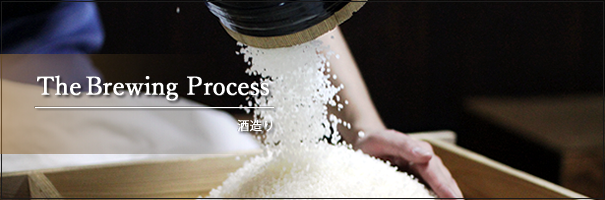

Polishing

Washing

Through previous experiments, we know exactly how long to wash the rice for it to absorb the ideal percentage of water. This manual process of exacting the absorption levels is conducted by use of a stop watch.

Steaming

The rice is steamed in a steaming vat known as a “koshiki” for 50 to 60 minutes. Factors like the strain of rice, the amount it has been polished down, whether it is to be used as koji rice or powdered rice (kakemai), and even the weather can affect how long the rice is steamed.

The OH vat system allows for a completely enclosed steaming process that results in perfectly steamed rice.

Cooling

Koji

The Kneading Process

Before the koji mold is spread over the rice, the rice is kneaded. The steamed rice is spread out and the temperature is adjusted. The starting temperature in koji making is very crucial.

Flipping

The rice needs to be flipped so that the heat on the top and bottom surfaces is distributed evenly. This process lowers the temperature of the rice 1°C, while perfectly equalizing the temperature of the rice throughout the entire batch.

Breaking Apart

Before taking the rice to the stacking room, this added process is significant in maneuvering the koji that has been sitting for a day.

The hardened koji is broken down by hand to its individual grains. Some breweries use machinery for this process, but since the fans in these machines cool down the koji batch, we prefer to do this manually. This may make the process more difficult, but we use extra hands to quickly execute this process.

Stacking 1

The rice is poured into the Koji Futa (wooden tray for koji).

Each tray is filled to about 1.8 L in volume.

Middle Step

Last Step

Shubo (Yeast Starter)

High Heat Mashing Process

The hot, steamed or powdered rice is added into the shubo yeasting tank lined with boiled koji water. The heat activates all the koji at once and the steamed rice begins to mash. As the temperature starts to drop, flask cultured yeast is added and heated again. Maintaining that heat for about a week spreads the yeast to an ideal consistency.

Preparation

Measuring the Koji Temperature

The water and powdered rice used in preparation are also adjusted until the moromi mash becomes reaches the right temperature.

Mizukoji - Koji Water

The shubo yeasting and the ensuing first, second, and third additional processes are repeated in the same order as follows: the koji is added to the prepared water and left to steep before adding the kakemai (powdered rice) to the mix. In following this order, the heated water extracts the enzymes from the koji. The powdered rice then absorbs those enzymes. The process of adding the koji to the prepared water is called “Mizukoji” which translates to Koji Water. The koji aspergillus oryzae mold at this point is no longer active but the byproduct enzymes keep working until the moromi mash is ready. The rice absorbs the enzymes and begins to break down from the inside out.

First Additional Process

Unlike the second and third additional processes, this “First Additional Process” is prepared in its own, smaller vat. If we were to prepare such a small volume into a large tank, the extra, empty space would cool the moromi mash too quickly.

Second and Third Additional Processes

After having been left to lay for a day, this process is repeated in the second additional process. The following day, the process is repeated for a third time. Through each step, the temperature is lowered incrementally. The temperature reduction seen in the second process is in the 8 to 10 degree range and the third is in the 6 to 8 degree range. Regardless of the process, the more the rice is polished and refined, the lower the temperature will be.

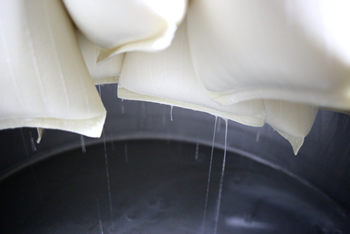

Hanging Vats: The Drip Filtration Process for Daiginjyo and Junmai Daiginjyo

All of the moromi mash is carefully poured into our vats to be hung.

Without adding pressure, the naturally percolating portions of the Daiginjyo sake are slowly collected.

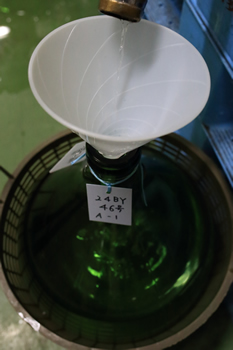

Bottling

The bottling process is done in a clean room in order to prevent any sort of contaminants from ruining the bottle.

All sake qualified as Junmai rank or higher is pasteurized. The bottle is pasteurized by flame then immediately cooled and stored in a chilled warehouse.

Sake that doesn’t require this process is immediately cooled and stored.

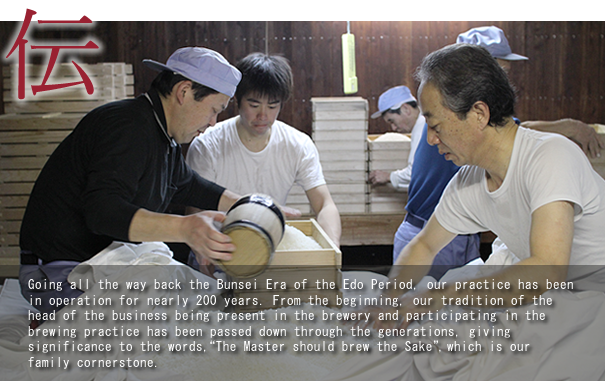

There are plenty of amazing technologies onsite. While standard education is very important, understanding the logic behind these technologies first hand is the first step in the learning and passing down of our traditions.

We regularly hold seminars with the Sake Brewers Association so as to ever improve Fukuoka Prefecture’s standards.

Good Japanese sake enriches your diet and is of significant cultural heritage.

- About the Brewers

- About the Sakamai (Rice for sake)

- About the Brewing Process

- About Yame

- About the Brewery

● To apply for Brewery Tour, fill out the Contact Form below.

-

Contact via Telephone

-

9:00 AM – 5:30 PM (Closed Weekends and Holidays)

FAX: +81 (0)943-23-2156

![]() 374 Motomachi YameFukuoka 834-0031, Japan

374 Motomachi YameFukuoka 834-0031, Japan